Technology and Robotic Storage Solutions in Indiana: Smart Warehousing Across Key Corridors

The Rise of Robotic Storage in Industrial Operations

What Is Robotic and Automated Storage?

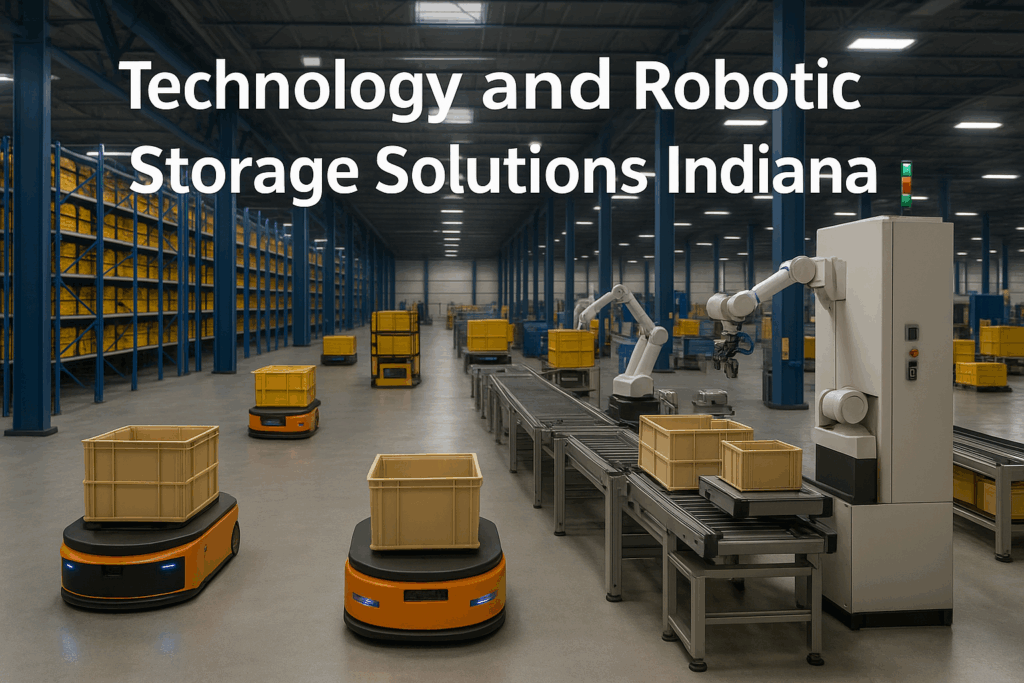

Robotic storage refers to storage systems powered by automation, including:

Automated Guided Vehicles (AGVs)

Autonomous Mobile Robots (AMRs)

Smart racks with vertical lift modules

These systems are optimized for high-throughput, scalable inventory handling—perfect for businesses with fast-moving SKUs or delicate products.

Why Robotics Improves Industrial Efficiency

Automated storage dramatically improves:

Order fulfillment speed

Picking accuracy

Inventory traceability

Labor cost savings

Industries Using Robotic Storage in Indiana

eCommerce and Omni-Channel Retail

Fast, accurate, and scalable robotic systems support:

Pick/pack operations

Real-time stock visibility

Same-day shipping fulfillment

Medical Device and Pharma Storage

Regulated industries benefit from:

Precision robotics

Temperature-sensitive environments

Secure inventory tracking

Automotive and Advanced Manufacturing

Manage parts bins, tools, and MRO inventory with automated solutions tailored for high-demand production.

Features of Our Technology-Enabled Storage Facilities

Automated Guided Vehicles (AGVs) and AMRs

These self-operating robots move goods across:

Warehouse aisles

Loading docks

Inventory staging zones

RFID-Tagged Inventory and Smart Racking

Track every item in real time with:

RFID inventory

QR scanning portals

Automated reordering

Warehouse Management System (WMS) Integration

All facilities are compatible with:

SAP, Oracle NetSuite, and Shopify integrations

Real-time dashboards

Barcode and thermal printing

Strategic Locations Across Indiana

Plainfield – Logistics Automation Near I-70

Home to one of Indiana’s largest logistics parks, Plainfield offers:

Robotic picking and fulfillment systems

Access to the Indianapolis Airport and I-70

Ideal for national distribution and same-day shipping

Northwest Indiana – High-Tech Fulfillment Close to Chicago

Hammond, Gary, and East Chicago provide:

Affordable alternatives to Chicago warehouses

Connectivity to rail and interstate hubs

Industrial parks equipped for automation

I-65 & I-69 Corridors – Regional Midpoint Automation

From Lafayette to Evansville, these corridors offer:

Mid-state automation zones

Support for agricultural tech, manufacturing, and food packaging

Cost-effective land with zoning for large robotics installations

I-70 & I-74 – eCommerce Nodes and Cross-Docking Zones

These east-west highways link major storage hubs with:

Rapid truck loading automation

Real-time inventory tracking at transit hubs

Robotic support for regional fulfillment centers

Marion County – Urban Innovation Hubs

Downtown and surrounding Marion County offers:

Tech-driven inventory systems for dense eCommerce

Clean storage zones for regulated industries

Access to high-skill labor and software integration firms

Lafayette – AgTech and Advanced Manufacturing Storage

Near Purdue and industrial manufacturers, Lafayette supports:

Smart inventory control for industrial parts

Integration with automated production lines

Precision storage for research and innovation labs

Benefits of Robotic Storage vs Traditional Systems

Speed, Accuracy, and 24/7 Efficiency

Robotic systems never tire, offering:

High picking speeds

Fewer human errors

Full operational capacity after hours

Reduced Labor Costs and Downtime

Save on:

Warehouse staffing

Manual operations

Lost time from human error

Precision for Delicate or Regulated Products

Robotics improve product safety and compliance for:

Medical devices

Chemicals

Aerospace components

How to Lease Tech-Enabled Storage With Us

Tour an Automated Facility

Visit our tech-ready sites across Indiana for:

Equipment demonstrations

Workflow consultations

Layout planning

System Compatibility Assessment

We’ll work with your team to determine:

WMS integration needs

Storage configuration based on SKU velocity

Automation onboarding timeline

Custom Storage Solutions Based on SKU Volume

From startups to enterprises, we offer:

Micro-fulfillment pods

Full-scale automated warehouses

Modular storage that scales with your growth

Frequently Asked Questions (FAQs)

What types of robotic systems are used?

We use:

AMRs (Autonomous Mobile Robots)

AS/RS (Automated Storage and Retrieval Systems)

Vertical lift modules and smart conveyors

Can your systems integrate with our ERP/WMS?

Yes. We support API and third-party software integrations with major systems like SAP, Oracle, QuickBooks, and Shopify.

Do you offer climate-controlled or clean zones?

Yes. We provide clean rooms and climate zones for pharmaceuticals, medical devices, and precision parts.

Are robotics available in outdoor storage areas?

While robotics is mostly indoor, we support semi-automated outdoor yards for container placement and large asset mapping.

What’s the onboarding timeline for automation?

Depending on system complexity, onboarding takes 1 to 4 weeks, including WMS testing and operator training.

Do you support tech startups or growing firms?

Yes. We provide modular solutions tailored to startups and offer flexible upgrades as demand grows.

Conclusion: Indiana’s Premier Robotic Storage Network for Modern Operations

As demand for speed, precision, and automation grows, technology and robotic storage solutions in Indiana are powering the next generation of warehousing and logistics. Whether you’re an eCommerce startup in Plainfield, a manufacturer in Lafayette, or a fulfillment partner in Northwest Indiana, our tech-forward facilities are ready to scale with you.

Experience the future of inventory storage. Schedule a tour today and transform your supply chain with intelligent automation.